How effective does the surface treatment of SUS410 stainless steel self-tapping screws improve its wear resistance?

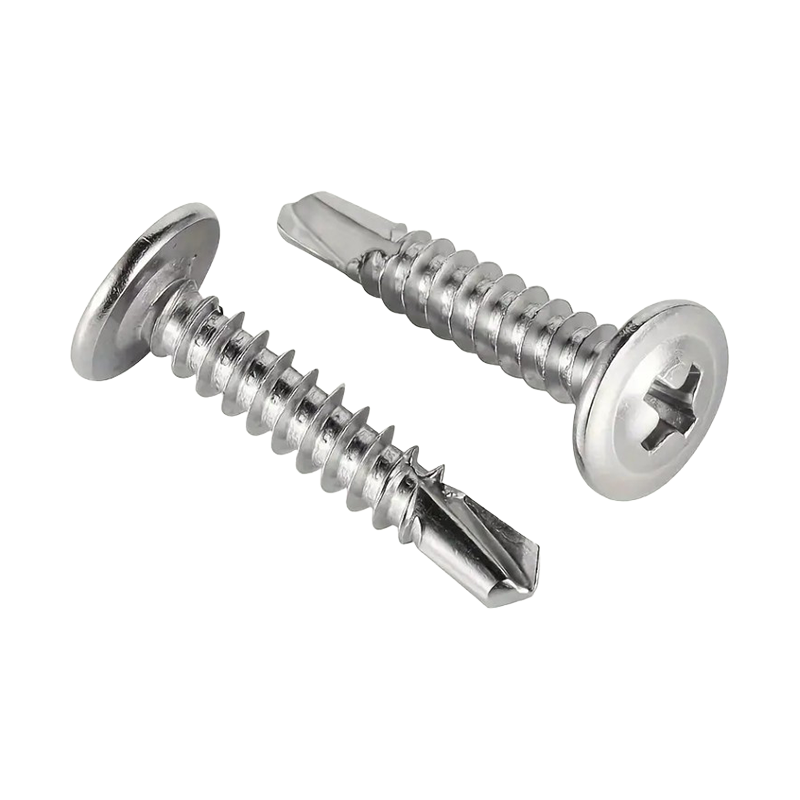

Among many screw types, SUS410 stainless steel self-tapping screws are widely used in construction, mechanical manufacturing and other fields due to their own characteristics. Surface treatment, as a key link in improving its performance, has attracted much attention on wear resistance.

SUS410 stainless steel is a martensitic stainless steel, with its main components including iron, chromium and carbon. It has the characteristics of high strength and high hardness, and has good wear resistance to a certain extent. However, in some working conditions where wear resistance is extremely high, relying solely on the characteristics of the material itself is far from enough. Taking a construction site as an example, SUS410 stainless steel self-tapping screws are used to fix building structural components. They are subject to wind, sun and rain for a long time, and have to withstand slight displacement friction between components. Without a suitable surface treatment, the screw surface is prone to wear and corrosion, which in turn affects the stability and safety of the connection.

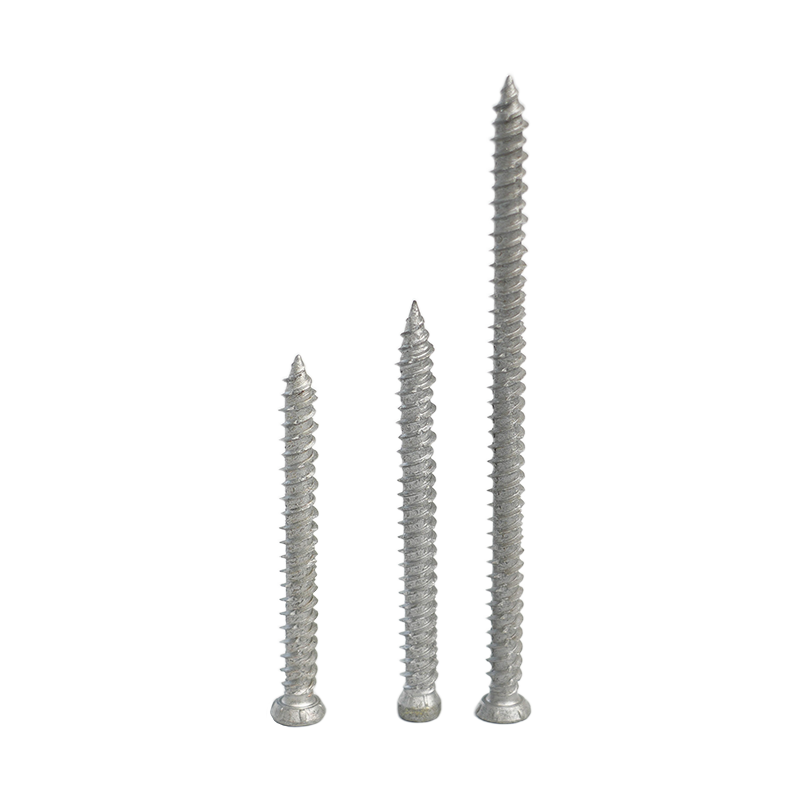

Common surface treatment methods have significant improvements in the wear resistance of SUS410 stainless steel self-tapping screws. Galvanizing treatment is a relatively common surface treatment method. By placing a layer of zinc on the surface of the screw, it can effectively improve its corrosion resistance and indirectly enhance its wear resistance. The zinc layer is like a protective film, which isolates the contact between the screws and the external corrosive media and reduces wear caused by corrosion. Experiments show that the galvanized SUS410 stainless steel self-tapping screws have a wear rate of about 30% - 40% lower than that of untreated screws in simulated humid industrial environments.

Nickel plating can also greatly improve the wear resistance of SUS410 stainless steel self-tapping screws. The nickel layer is hard and smooth, which not only improves the hardness of the screw surface, but also reduces the coefficient of friction. In the field of mechanical manufacturing, the use of nickel-plated SUS410 stainless steel self-tapping screws can reduce friction loss during tightening and use of screws. Relevant data show that the nickel-plated screws have a wear reduction of about 50% compared to the untreated screws in a high-frequency mechanical vibration environment, which greatly extends the service life of the screws.

A company specializing in the production of screws, such as Wuxi Sharp Metal Products Co., Ltd., pays great attention to the surface treatment process in the production process of SUS410 stainless steel self-tapping screws. The company has its own laboratory and advanced testing equipment, and strictly inspects each batch of surface-treated screws to ensure that the surface-treated screws can meet the needs of different customers. They will provide customers with the most suitable surface treatment solution according to the different industries and application scenarios of the customers, and give full play to the performance advantages of SUS410 stainless steel self-tapping screws.

The surface treatment of SUS410 stainless steel self-tapping screws has obvious effect on improving its wear resistance. Different surface treatment methods use different principles to improve the wear resistance of screws from the aspects of reducing corrosion, increasing hardness, reducing friction coefficient, etc., so that they can better adapt to various complex working conditions. In the future, with the continuous advancement of technology, the surface treatment process will continue to be optimized, further tapping the performance potential of SUS410 stainless steel self-tapping screws and providing more reliable fastening solutions for the development of various industries.

+86-15052135118

+86-15052135118

Español

Español

Get In Touch

Get In Touch