Why are Screwdriver Bits for Self-Tapping Screws so "sensitive" to torque?

The groove design of self-tapping screws is often more targeted. Although the head form (such as cross, square or star) seems conventional, it has extremely high requirements for torque transmission direction, contact angle and force application accuracy in actual operation. Any slight deviation may cause uneven stress between the bit and the screw, which may lead to problems such as slipping, skipping or breaking. Once such errors occur, they will not only disrupt the rhythm of the operation, but may also cause damage to the connection parts and even affect the stability of the overall structure.

The professional design of Screwdriver Bits for Self-Tapping Screws is precisely to solve this pain point. They are specially optimized in terms of size, shape and material hardness to ensure a close fit with the screw head during the screwing process, thereby achieving accurate torque transmission. Only when the applied force acts on the screw body completely along the designed trajectory can the self-tapping screw be guaranteed to penetrate the material smoothly and be firmly embedded in it. This high degree of fit is not an "invisible" advantage, but it plays a role quietly in every tightening.

Subtle differences in structure often determine the world of difference in the use experience. Screwdriver Bits for Self-Tapping Screws focus on the sharpness of corners, matching of groove angles, and overall rigidity control in the manufacturing process. This not only improves the tool's adaptability to high torque, but also enhances its stability under high-frequency use. Since self-tapping screws will produce reverse stress fluctuations during work, ordinary screwdriver bits are prone to slight deviations during repeated force, which will cause screw wear, hole deviation, or even loosening over time. Professional screwdriver bits can firmly "lock" the direction of force, stably introduce torque into the screw, and complete fast and precise fixing actions.

In addition, the wear resistance of this type of screwdriver bit cannot be ignored. Faced with high-intensity and long-term operation requirements, if the tool material does not have sufficient surface hardness or structural strength, it is very easy to be damaged in high-pressure friction, thereby affecting the operation efficiency. Screwdriver Bits for Self-Tapping Screws improve durability through fine heat treatment or special coating process, so that it can still maintain the original bite force and force accuracy in repeated use.

When people focus on work efficiency, they often ignore the subtle coordination between tools. On the contrary, the real efficiency comes from the precise coordination of every detail. The function of self-tapping screws does not rely entirely on their own structure, but also highly depends on whether the matching bit can complete the high-efficiency force transmission and precise direction control. The design logic of Screwdriver Bits for Self-Tapping Screws in this aspect is the product of a deep understanding of the physical properties of screws, and it is also a concrete embodiment of the modern tool industry's concept of "details determine success or failure".

In theory, torque is a moment acting on an object. It not only requires sufficient strength, but also requires the direction to be completely consistent with the axis. A slight deviation will form lateral stress, affecting the connection effect. During the screwing process of the self-tapping screw, its tip is "opening", and the force on the screw head must be steadily pushed downward. If the Screwdriver Bits cannot stably output linear torque, it is very easy to cause the screw to deflect or break, which is unacceptable for any precision assembly work.

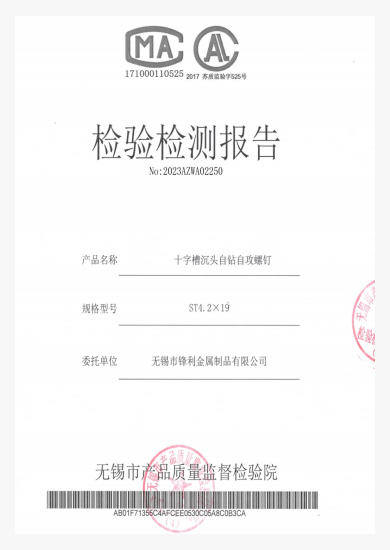

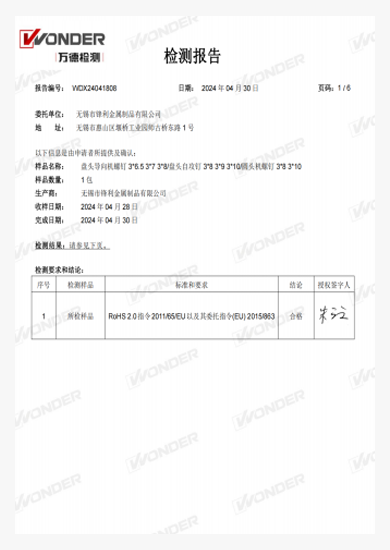

It can be said that Screwdriver Bits for Self-Tapping Screws is not a "universal substitute", but a professional tool for specific structures and specific tasks. Wuxi Sharp Metal Products Co., Ltd. is a professional enterprise that produces and sells screws. With a high degree of morphological accuracy and structural toughness, it ensures that each screw can maintain a consistent force state during the application process, thereby achieving high-quality and high-consistency tightening effects. Its "sensitivity" to torque is the embodiment of its professional performance; its "stubbornness" to the direction of force is the basis for its quality assurance.

With the continuous evolution of tool design, people's attention to detail accuracy is also increasing. The professionalization trend embodied by Screwdriver Bits for Self-Tapping Screws is the epitome of the modern tool industry moving towards higher standards. The use of tools in the future may no longer be a crude "just work if it works", but a refined and specialized "must be just right". Understanding this change is the first step towards efficient operations and professional standards.

+86-15052135118

+86-15052135118

Español

Español

Get In Touch

Get In Touch