Compared with other types of connectors, what are the advantages of steel nails and rivets in terms of connection strength?

From the perspective of connection principle, the design of steel nails and rivets makes them unique in terms of strength performance. Steel nails rely on strong impact force to directly nail into the connected materials, forming a tight mechanical bite with the materials. In actual operation, construction workers use nail guns or hammers to apply external force, and steel nails penetrate the surface of the material at a very fast speed. Taking construction as an example, in the construction of wooden houses, steel nails can quickly connect wooden boards tightly. The surface of steel nails often has threads or grooves. When nailed into wood, these special structures will entangle and hook with wood fibers, just like trees taking root in the soil, tightly grasping the surrounding materials, thereby generating strong pull-out and shear resistance. Even if encountering long-term vibration or external force impact, the connection can maintain stability. Just like some areas located in earthquake zones, when building wooden houses, the use of high-quality steel nails can effectively enhance the seismic performance of the house and reduce structural damage caused by earthquakes.

The connection method of rivets is also exquisite. It inserts the nail rod at one end into the prefabricated hole of the connected part, and then rivets the other end to deform the nail rod and fill the entire hole to form a strong rivet head. In the field of aerospace, rivets are widely used in the fuselage structure of aircraft. During the flight of the aircraft, the fuselage is subjected to huge pressure changes, aerodynamics, engine vibration and other complex stresses. When installing rivets, pressure is applied through special riveting equipment to make the nail rod plastically deform in the hole, which not only forms a strong clamping force between the connected parts, but also eliminates the gap in the connection part due to the deformation and filling of the rivet itself, making the connection tighter. This tight and stable connection method ensures that the fuselage structure of the aircraft can still maintain high strength during high-speed flight and extreme environments, ensuring the safety and stability of the flight process.

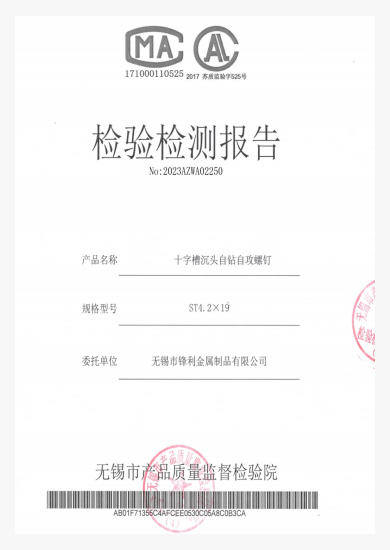

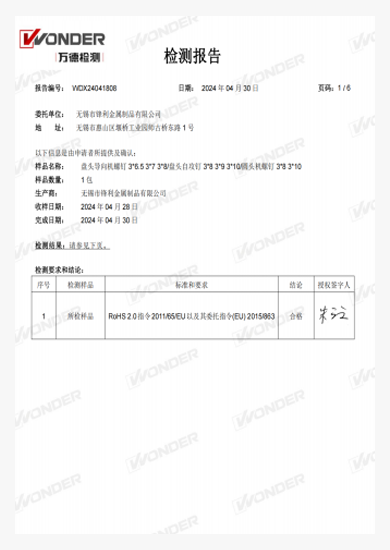

Compared with threaded connectors such as bolts and screws, steel nails and rivets have more significant advantages in connection strength. The connection strength of bolts and screws depends largely on the matching of threads and the tightness of nuts. Under the action of long-term vibration or alternating load, the thread is easy to loosen, and the nut may also fall off due to vibration, resulting in connection failure. Take heavy trucks as an example. When driving on bumpy roads, the engine, chassis and other parts of the vehicle will produce continuous vibration. If the parts connected by bolts are not properly prevented from loosening, the bolts may gradually loosen over time, affecting the normal operation of the vehicle and even causing safety accidents. Once the steel nails and rivets are connected, they form a whole with the connected materials and there is no risk of loosening. In the process of automobile manufacturing, the rivets supplied by Wuxi Sharp Metal Products Co., Ltd. are widely used in the connection of body frames. These rivets can withstand various complex stress changes during vehicle driving. Whether it is the impact caused by acceleration and deceleration, or the twisting force of the body when turning, they can always maintain high strength of the connection parts to ensure the safety of the vehicle. Although chemical connectors such as glue can provide good bonding force in some cases, they are still not comparable to steel nails and rivets in terms of strength. The bonding effect of glue is greatly affected by factors such as ambient temperature and humidity. Over time, the glue may also age and fail, resulting in a decrease in connection strength. In the installation of outdoor billboards, if glue is used to connect the frame and supporting structure of the billboard, the glue may become soft and lose its stickiness under high temperature and exposure; in a humid and rainy environment, the glue is easily affected by moisture, and the bonding performance is greatly reduced. Steel nails and rivets are made of metal, have good weather resistance and durability, and can maintain stable connection strength for a long time in various harsh environments. In the connection of outdoor building facilities, steel nails can easily cope with natural conditions such as wind, sun, rain and snow erosion to ensure the stability of the structure. For example, in the construction of piers at the seaside, steel nails can resist the corrosion of seawater and the long-term blowing of sea breeze to ensure the safe use of piers.

In actual application scenarios, the strength advantages of steel nails and rivets have been fully verified. In the door and window installation industry, steel nails produced by Wuxi Sharp Metal Products Co., Ltd. are indispensable fixed connection elements. Doors and windows need to withstand frequent opening and closing, the impact of wind and rain, and thermal expansion and contraction caused by temperature changes during long-term use. Steel nails can firmly connect the door and window frames to the wall with their strong connection strength, ensuring the structural stability and long-term durability of the door and window system. In the winter in the north, doors and windows will shrink due to the decrease in temperature, and steel nails can still tightly fix the frame to prevent the gap from increasing and affecting the sealing. At the same time, this firm connection also provides good sealing performance for doors and windows, enhances sound insulation, heat insulation and waterproof effects, and improves the comfort of living and use.

In the field of furniture manufacturing, steel nails and rivets also play an important role. Furniture will be subject to various external forces in daily use, such as load-bearing and moving, which requires the connectors to have sufficient strength. The various metal accessories produced by Wuxi Sharp Metal Products Co., Ltd. can meet the connection needs of different parts of furniture. For example, in the frame connection of large solid wood furniture, rivets can tightly fix heavy wood. Although the traditional mortise and tenon structure furniture is beautiful and has a certain strength, in the process of modern industrial production and transportation, the mortise and tenon structure may become loose due to collision and other reasons. The rivet connection method can ensure that the furniture will not loosen or deform during long-term use without destroying the beauty of the wood, which not only improves the functionality and durability of the furniture, but also ensures its beauty. Some high-end customized solid wood dining tables use rivets to connect the table legs and the tabletop frame, which can remain stable even if they are frequently moved and loaded.

Electronic equipment assembly has extremely high requirements for the accuracy and strength of connectors. The screws, self-tapping screws and other products produced by our company are widely used in the electronic component industry. In the process of electronic equipment assembly, although a large number of screws are used, in some key parts, steel nails and rivets have become better choices due to their unique strength advantages. For example, in the fixed connection between the printed circuit board (PCB) and the chassis, rivets can provide a stable and reliable connection to prevent the circuit board from shifting due to vibration during the operation of the equipment, ensure the stable connection between electronic components, and ensure the normal operation of electronic equipment. In some industrial-grade computers, since the equipment needs to operate in a complex industrial environment, it will face strong vibration and electromagnetic interference. At this time, using rivets to fix the PCB board can effectively avoid problems such as poor line contact caused by vibration and improve the reliability and stability of the equipment.

With the development of science and technology, the materials and manufacturing processes of steel nails and rivets are also constantly innovating. Nowadays, in addition to traditional carbon steel materials, steel nails and rivets made of stainless steel, aluminum alloy and other materials are also widely used in different fields. Steel nails and rivets made of stainless steel have excellent rust resistance and are suitable for humid and corrosive environments; aluminum alloy plays an important role in lightweight design of aerospace and automobiles due to its light weight and high strength. In terms of manufacturing technology, the application of advanced processes such as cold heading and hot forging makes steel nails and rivets more precise and more stable in strength. Wuxi Sharp Metal Products Co., Ltd. keeps up with the development trend of the industry, continuously increases R&D investment, introduces advanced production equipment and technology, and continuously optimizes and innovates products to meet the market's growing demand for high-quality connectors.

The advantages of steel nails and rivets in connection strength come from their unique design and connection principle. Compared with other types of connectors, they can always maintain stable and reliable connection performance in various complex application scenarios. With strict control of product quality and continuous innovation, we give full play to the advantages of metal connectors such as steel nails and rivets, which are widely used in many industries, providing a solid guarantee for the development of various industries. With the continuous advancement of technology, the performance of steel nails and rivets will continue to be optimized, playing an important role in more fields, and contributing more to the development of modern industry and construction.

+86-15052135118

+86-15052135118

Español

Español

Get In Touch

Get In Touch