Material characteristics and mechanical properties of cement screws

1. Definition and application of cement screws

Cement screws, also known as concrete screws or chemical anchor screws, are high-strength fasteners designed for hard substrates such as concrete and masonry. They are firmly fixed by mechanical engagement or chemical bonding between the thread and the substrate, and are widely used in building structure reinforcement, curtain wall installation, pipeline fixing, equipment base and other fields. Due to the brittle nature of concrete, cement screws must have high tensile and shear resistance, and adapt to complex environments such as vibration and humidity.

2. Analysis of core material characteristics

The material selection of cement screws directly affects their durability and mechanical performance. The mainstream materials can be divided into three categories:

(1) Carbon steel (surface galvanized/phosphating)

Carbon steel screws are low in cost and high in strength (up to grade 8.8), but are prone to rust and need to be galvanized or phosphated to improve their anti-rust performance. Ordinary galvanized layers may cause "white rust" in humid environments and are suitable for fixing in short-term or dry environments.

(2) Stainless steel (A2/A4 grade)

A2 (304 stainless steel) is resistant to general corrosion, and A4 (316 stainless steel) contains molybdenum, which is more resistant to salt spray and chemical corrosion, and is suitable for high humidity and high salt environments such as coastal areas and chemical plants. However, the strength of stainless steel is slightly lower than that of alloy steel (usually 5.8~8.8 grade), and strength and corrosion resistance need to be weighed.

(3) Alloy steel (10.9/12.9 grade high strength)

By adding elements such as chromium and vanadium to improve strength (tensile strength ≥1000MPa), it is often used for heavy structural anchoring. However, because the alloy components are prone to rust, Dacromet coating or epoxy resin spraying is required to balance strength and corrosion resistance.

Key material indicators:

Hardness (HRC 22-32): Too high can easily lead to brittle cracking during installation, and too low can lead to insufficient shear resistance.

Salt spray resistance: High-quality coatings or stainless steel must pass a salt spray test of more than 500 hours (such as ASTM B117).

3. Key parameters and test methods of mechanical properties

The mechanical properties of cement screws must comply with standards such as ISO 898-1 and ASTM F1554. The core parameters include:

(1) Tensile strength

The tensile strength of high-strength screws (such as grade 10.9) must be ≥1000MPa. The actual bearing capacity is also affected by the strength of concrete. For example, the ultimate tensile strength of M12 screws in C30 concrete can reach 25kN.

(2) Shear strength

Usually 60%~70% of the tensile strength. Thread design (such as double-thread) can improve shear performance. Dynamic loads must be simulated during testing (such as vibration table tests).

(3) Torque and preload

The installation torque must be precisely controlled. Excessive torque will cause cracking of the substrate or thread slippage. For example, the recommended torque for M10 screws is 40~50N·m, and it should be used with a torque wrench.

(4) Embedment Depth

The minimum embedment depth is generally 5 times the diameter of the screw (e.g., M8 screws need to be embedded more than 40 mm). Too shallow will significantly reduce the bearing capacity.

4. Engineering matching of materials and mechanical properties

Highly corrosive environment: A4 stainless steel or plated alloy steel is preferred, sacrificing a small amount of strength in exchange for long-term durability.

Super high-rise buildings: 10.9 grade alloy steel + epoxy coating is used to meet the requirements of earthquake resistance and wind pressure resistance.

Dynamic load scenarios (such as bridges): The life of the screws needs to be verified through fatigue tests (such as 2 million cycles of loading).

How to correctly select concrete fasteners? Analysis of load, substrate conditions and environmental factors

1. Core selection factors of concrete fasteners

The selection of concrete fasteners (such as expansion bolts, chemical anchor bolts, self-tapping screws, etc.) needs to consider the following factors:

Load requirements

Static load vs. dynamic load: High vibration environment (such as mechanical equipment fixing) requires the use of earthquake-resistant anchor bolts (such as chemical anchor bolts or special expansion bolts).

Load-bearing grade: Wuxi Sharp's carbon steel screws and stainless steel self-tapping screws can meet different strength requirements, for example:

Light fixation (such as door and window accessories): Use self-tapping screws (such as cement screws).

Heavy structure (such as steel structure base): High-strength expansion bolts or chemical anchoring systems are recommended.

Substrate conditions

Concrete strength (C20/C30/C50, etc.): Low-strength concrete requires fasteners with moderate expansion force to avoid cracking.

Substrate thickness: Thin substrates require penetrating anchor bolts (such as Sharp's fiberboard screws), and thick substrates can use deep-buried chemical anchor bolts.

Environmental factors

Humidity/corrosive environment: For coastal or chemical scenes, it is recommended to use Wuxi Sharp's stainless steel self-tapping screws (such as A2/A4 grade stainless steel), which are more corrosion-resistant.

Temperature changes: Materials with high thermal stability (such as chemical anchor colloids) should be selected in extreme temperature difference environments.

2. Wuxi Sharp's product and technical advantages

As a professional fastener manufacturer established in 1993, Wuxi Sharp Metal Products Co., Ltd. provides the following support:

Diversified product lines

Special fasteners for concrete: such as cement screws (suitable for lightweight concrete) and carbon steel expansion bolts (high load scenes).

Supporting solutions: In the installation of doors, windows and exterior walls, we can combine our door and window accessories trading business to provide a one-stop fastening solution.

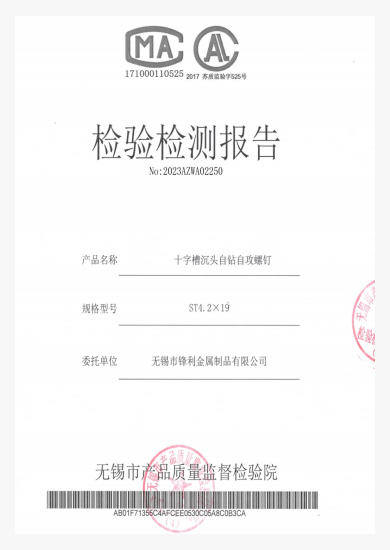

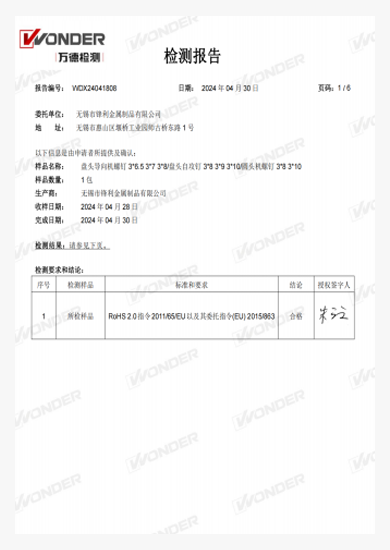

Production and quality control

A 6,000 square meter factory, 100+ equipment and 800 tons of inventory ensure rapid response to order needs.

Annual output of 2,000 tons, strictly follow ISO standards to ensure product consistency.

Industry application experience

Since 2000, we have been deeply involved in the field of doors and windows engineering. Our products are widely used in aluminum alloy engineering doors and windows, home decoration systems, and are compatible with domestic and foreign building standards (such as GB, ASTM).

+86-15052135118

+86-15052135118

Español

Español

Get In Touch

Get In Touch