How do carbon steel screws play a key role in industrial connections?

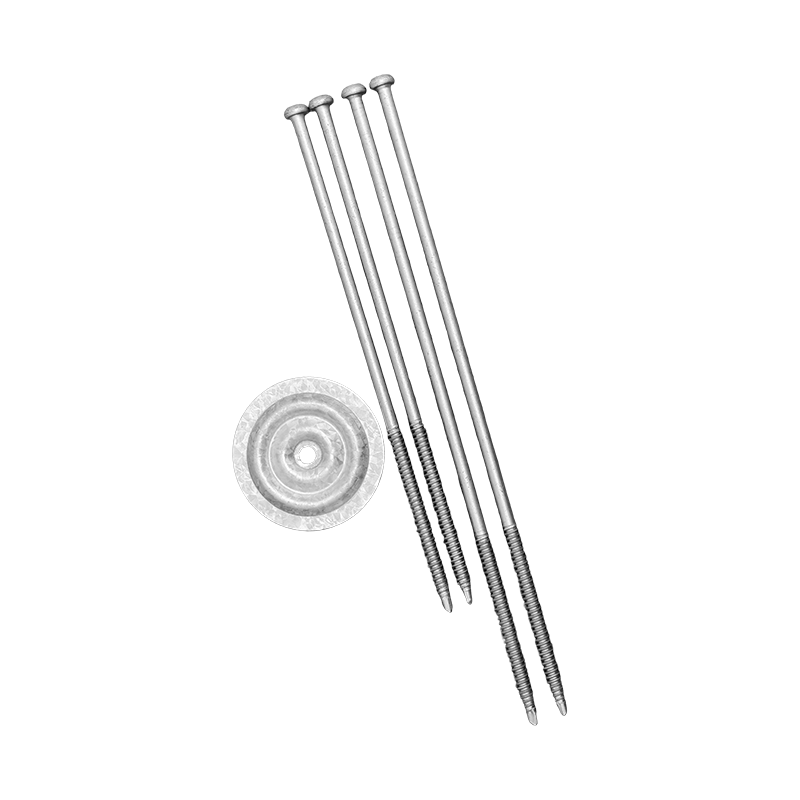

In modern manufacturing and construction, fasteners are the core elements of building a solid structure. Among the many fastening materials, Carbon Steel Screws stand out with their excellent performance and cost-effectiveness, becoming an indispensable choice for industrial connections. From tiny electronic components to huge infrastructure, carbon steel screws are everywhere. Why is this seemingly ordinary part so important? How does it play a key role in the connection system?

As a metal material, carbon steel has extremely high mechanical strength and durability. It is composed of iron and a certain proportion of carbon elements. Although the carbon content is not high, it determines its hardness and tensile strength. Compared with other materials such as stainless steel, copper or plastic, carbon steel screws have obvious advantages in structural bearing. Especially in application scenarios that need to withstand high loads or frequent vibrations for a long time, they can provide more reliable connection guarantees.

Carbon steel screws also have excellent processability and heat treatment performance. During the manufacturing process, through heat treatment processes such as annealing and quenching, its mechanical properties can be further optimized, so that the screws can achieve a better balance between strength, hardness and toughness. In order to enhance its surface corrosion resistance, manufacturers usually use electrogalvanizing, hot-dip galvanizing, phosphating or Dacromet coating for surface treatment. This not only improves the applicability of screws in different environments, but also extends their service life.

Cost control is also a major advantage of carbon steel screws. Compared with high-priced special alloys or high-nickel stainless steel, carbon steel raw materials are easier to obtain and the production process is more mature, so the overall manufacturing cost is lower. This feature makes it an ideal choice for mass production, especially in industries such as construction, machinery manufacturing, automobile assembly, and home hardware, which can help companies effectively control budgets while ensuring quality.

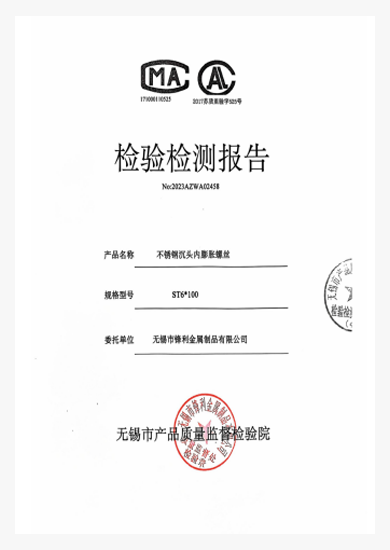

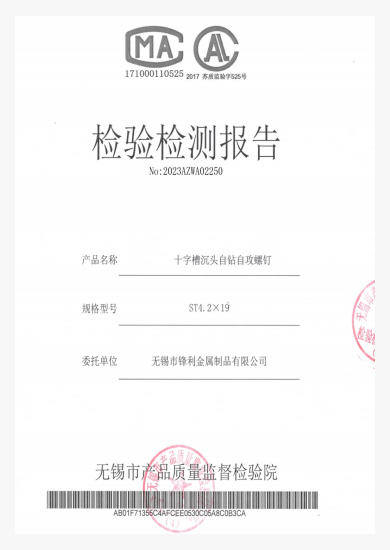

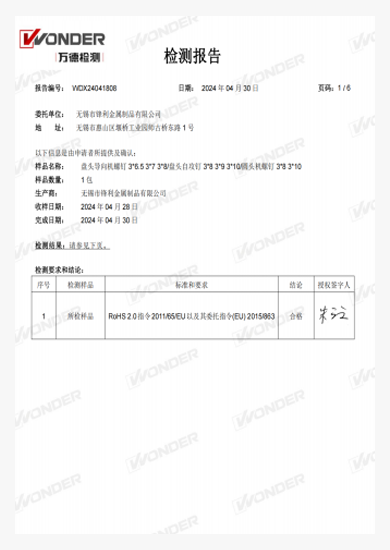

Wuxi Sharp Metal Products Co., Ltd. provides strong technical support and quality assurance for the development of carbon steel screws. As one of China's leading fastener suppliers, Wuxi Sharp Metal has a complete automated production line and advanced quality inspection system. From raw material procurement, mold development, thread rolling to heat treatment and surface treatment, all strict quality control processes are implemented. The company's products not only meet many international standards such as ISO, DIN, ANSI, but can also be customized according to customer needs. They are widely used in many countries and regions and are deeply trusted by domestic and foreign customers.

Wuxi Sharp Metal Products Co., Ltd. attaches great importance to R&D investment and customer service, actively explores the application of new surface treatment processes and environmentally friendly materials, and is committed to creating more competitive carbon steel screw products. In the context of the current global manufacturing industry's transformation towards efficiency, greenness and sustainability, the company continues to innovate and develop to provide customers with higher quality and more efficient fastening solutions.

The reason why carbon steel screws play a key role in industrial connections is not only due to their excellent strength, processability and cost advantages, but also due to the continuous investment of high-quality manufacturers such as Wuxi Sharp Metal in product quality and technical support. With the continuous expansion of application scenarios and the continuous advancement of process technology, carbon steel screws will play a more important role in more industries and become a solid force to promote the safe and efficient operation of industrial infrastructure.

+86-15052135118

+86-15052135118

Español

Español

Get In Touch

Get In Touch