Selection and installation specifications of anchor bolts in construction projects

1. Key factors for the selection of anchor bolts

In construction projects, the selection of anchor bolts needs to comprehensively consider factors such as substrate type (concrete, steel structure), load requirements (static load/dynamic load), and environment (corrosion, vibration). As a professional fastener manufacturer, Wuxi Sharp Metal Products Co., Ltd. provides anchor bolts of various materials, including:

Carbon steel anchor bolts: suitable for general building structures, economical and durable.

Stainless steel anchor bolts (such as A2/A4): corrosion-resistant, suitable for humid or chemical environments (such as basements, coastal projects).

Chemical anchor bolts: for high-load or cracked concrete substrates, used with epoxy resin glue.

Company advantages: Relying on a 6,000 square meter production base and more than 800 tons of inventory, we can quickly respond to various anchor bolt customization needs to ensure compliance with GB, ASTM, DIN and other standards.

2. Installation specifications and construction points

Substrate pretreatment

The concrete needs to reach the design strength (usually ≥C20), and the debris should be cleaned after drilling.

The contact surface of the steel structure should be rust-free and flat.

Drilling and anchoring

Mechanical expansion anchor bolts: The hole diameter and depth must strictly match the bolt specifications (such as M12 anchor bolts corresponding to 14mm holes).

Chemical anchor bolts: After injection, they need to be left to solidify (the time is adjusted according to the ambient temperature).

Torque control

Use a torque wrench to tighten, avoid over-tightening to cause slipping or too loose to affect the pull-out resistance.

Company technical support: We can provide customers with installation guides and load calculation references to ensure construction compliance.

Selection Guide for Expansion Bolts in Construction Projects: From Light Fixing to Heavy Support

In construction projects, the selection of expansion bolts directly affects the stability and safety of the structure. As a professional fastener company integrating large-scale production, warehousing, and R&D, we provide customers with a full range of expansion bolt solutions to meet different needs from light fixation to heavy support with our strict quality control system, advanced production technology, and high-quality after-sales service.

1. Light Fixing (Low-Load Applications)

Applicable scenarios: hanging light decorations, cable trays, door and window fixings, etc.

Recommended products:

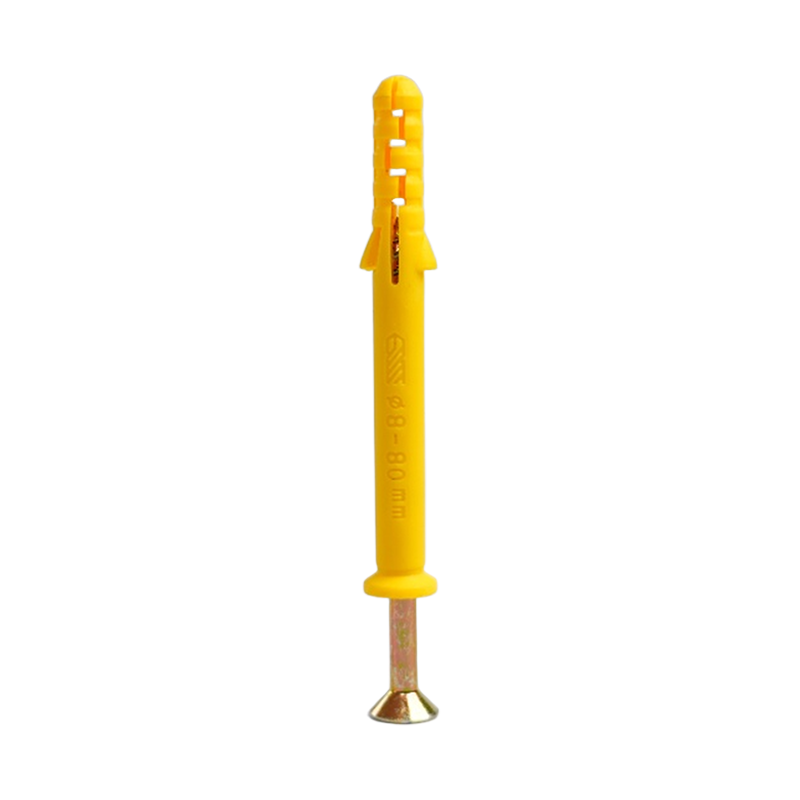

Nylon anchors (Plastic Anchors): suitable for low-strength substrates such as hollow bricks and gypsum boards.

Light Metal Expansion Bolts (M6-M8): used for light fixation of concrete or solid bricks.

Company advantages:

Adopting high-toughness nylon & galvanized steel materials, rust-proof and corrosion-resistant.

Automated testing process ensures that each batch of products meets ISO standards.

2. Medium-Load Applications

Applicable scenarios: steel structure connection, pipe support, mechanical equipment base fixing, etc.

Recommended products:

Sleeve Anchors (M10-M12): provide stable anchoring force through friction between expansion sleeve and hole wall.

Double Expansion Anchors: suitable for vibration environment, with stronger tensile strength.

Company advantages:

Full process quality control to ensure that the tensile strength of the bolts is ≥8.8.

Provide anti-loosening design (such as locking gasket) to avoid loosening after long-term use.

3. Heavy-Duty Applications

Applicable scenarios: bridges, high-rise building curtain walls, heavy machinery anchoring, etc.

Recommended products:

Heavy-Duty Chemical Anchors: bonded by epoxy resin glue, with extremely high bearing capacity.

High-strength expansion bolts (M16-M24): suitable for high-strength concrete above C30.

Company advantages:

The independently developed high-carbon steel heat treatment process makes the product tensile strength reach 10.9 grade and above.

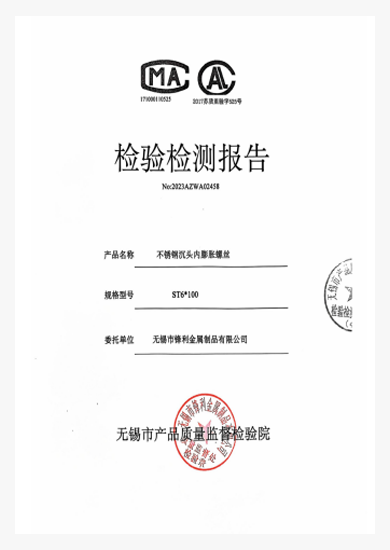

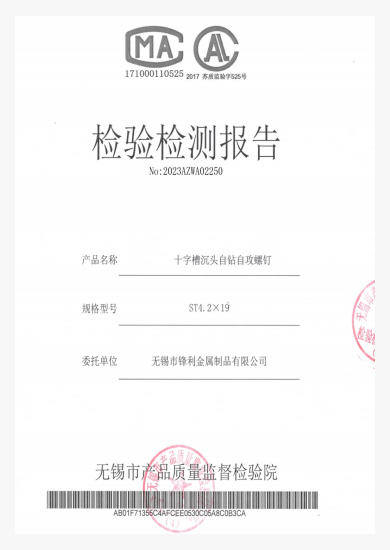

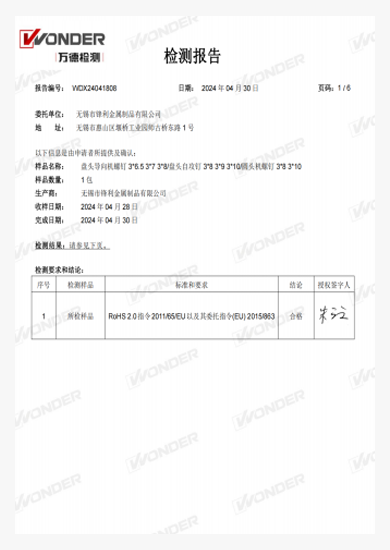

Third-party test report support, in line with international standards such as GB, ASTM, DIN, etc.

Why choose us?

Scaled production: large storage capacity, rapid response to customer needs.

Strict quality control: full-process quality inspection system from raw materials to finished products.

Technological innovation: continuous research and development of special expansion bolts with high corrosion resistance and vibration resistance.

Global service: products are exported overseas and have won long-term trust from domestic and foreign customers.

+86-15052135118

+86-15052135118

Español

Español

Get In Touch

Get In Touch