There are many kinds of machine screws, which are usually designed according to unified international standards (such as DIN, GB, ANIS, etc.) to ensure compatibility with matching nuts or threaded holes and good interchangeability. Common types include hexagonal, round head, countersunk head screws, etc. Machine screws are widely used in various types of mechanical equipment, industrial production, construction engineering, automobile manufacturing, electronic equipment, home appliance assembly and other fields.

|

Material |

Carbon steel |

|

Head type |

Countersunk head, round head, hexagonal head, etc. |

|

Hardness |

Hardness of the material itself |

| Thread size | Length | ||||||

| 3 | 6,8,10,12,14,16,20,25,30mm | ||||||

| 4 | 8,10,12,14,16,20,25,30,35,40,50,60,70,80,90,100mm | ||||||

| 5 | 10,12,14,16,20,25,30,35,40,50,60,70,80,100mm | ||||||

| 6 | 10,12,14,16,20,25,30,35,40,50,60,70,80,100mm | ||||||

Product Features

- Material Options:Available in stainless steel (A2/A4), carbon steel, and alloy steel grades to match required tensile strength and corrosion resistance for industrial environments.

- Head and Drive Variants:Offered in pan, flat (countersunk), round, and socket styles with drive types including Phillips, Pozidriv, slotted, hex, and Torx to suit automated assembly and manual installation.

- Thread and Size Range:Metric and imperial threads available, typically from M1.6 to M12 and UNC/UNF equivalents, with lengths from a few millimetres to over 100 mm for equipment assembly, electrical enclosures, and PCB mounting.

Product Description

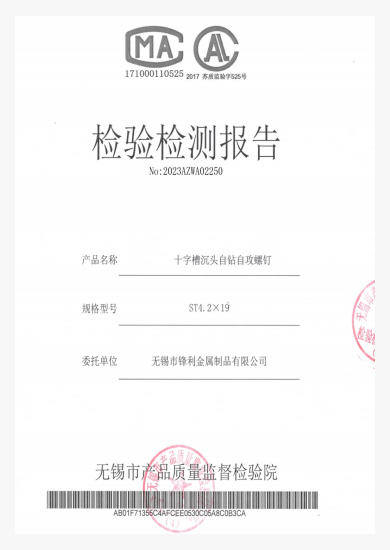

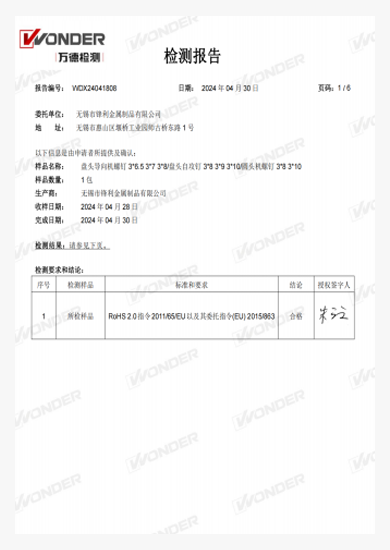

Machine screws are engineered for fastening components into pre-tapped holes or with mating nuts in mechanical assemblies. Manufacturing adheres to standardised thread forms and dimensional tolerances suitable for mass production and repeatable assembly processes. Production processes include cold heading, thread rolling, and precision machining where required. Surface finishes and coatings such as passivation, zinc plating, black oxide, and mechanical galvanizing are applied according to corrosion protection requirements. Quality control is performed under documented production procedures and batch traceability; typical supply documentation can include material certificates and inspection records. Common compliance and management frameworks applied during manufacture include ISO 9001 based quality control and material conformity checks; electrical and electronic applications often require RoHS verification when specified.

Application Areas

This product is suitable for the following scenarios:

- Mechanical assemblies requiring fasteners into pre-tapped holes such as gearboxes, housings, and machine frames.

- Electrical and electronic enclosures, PCB mounting where controlled clamping force and precise thread engagement are required.

- Aerospace subassemblies, automotive interior components, and industrial automation equipment where specified material and surface treatments are requested.

- Commercial and construction fixtures that call for metric or imperial machine screw sizes and standardised drive types for installation efficiency.

FAQ

1. What is the difference between a machine screw and a self-tapping screw, and how do I choose between them for a tapped hole?

A machine screw is designed to be used with a pre-formed (tapped) thread in a mating component or with a nut; it relies on the existing internal thread for full engagement. A self-tapping screw forms or cuts its own mating thread in softer materials and is selected when tapping operations are to be avoided. Choose a machine screw when the assembly has a standard tapped hole sized to metric or imperial thread standards, when predictable clamping force and repeatable torque values are required, and when disassembly is expected. Select a self-tapping option only when the substrate permits thread formation and when long-term fatigue performance under cyclic loading is not critical. For retrofit or repair where tapped holes are damaged, using a thread insert (e.g., helicoil) with a machine screw restores correct engagement.

2. How do I determine the correct torque and material for machine screws to avoid stripping or corrosion in my application?

Determining correct torque requires consideration of screw diameter, thread pitch, material strength class, lubrication, and the mating material. Refer to standard torque tables for the specific thread size and material class as a starting point; verify with assembly testing under expected load and temperature. Use higher strength classes (for example, 8.8 or 10.9 for steel) where shear or tensile loads are significant, but ensure mating components can accommodate the applied clamping force. For corrosive environments or outdoor use, choose corrosion-resistant materials such as A4 stainless steel or apply appropriate coatings; avoid galvanic couples by matching materials where possible. When in doubt, perform a sample assembly and a torque-to-yield or clamp-load measurement to validate the selected torque and fastener material for service conditions.

-

In the world of woodworking, furniture assembly, and cabinetry, choosing the right fastener is crucial for the strength, durability, and aesthetics of the final product. Among the specialized options available, chipboard...

READ MORE -

In the vast world of fasteners, carbon steel screws stand as a fundamental and versatile component, essential for countless construction, manufacturing, and DIY projects. Their strength, affordability, and wide availabil...

READ MORE -

In the vast world of fasteners, selecting the right screw material is critical for the longevity, safety, and performance of any assembly. Among the various options, SUS410 stainless steel screw stands out as a popular a...

READ MORE

+86-15052135118

+86-15052135118

Español

Español

Get In Touch

Get In Touch