-

Hardness Testing MachineThe hardness testing machine detects the hardness of the screw material and the effect of heat treatment to ensure that the performance meets the standard and optimizes the production process. At the same time, it monitors batch consistency, prevents failure risks, and accurately verifies the hardness and surface hardening layer of key parts such as threads to ensure that the product meets international standards and improves the reliability and market competitiveness of screws.

-

Hardness Testing MachineThe hardness testing machine detects the hardness of the screw material and the effect of heat treatment to ensure that the performance meets the standard and optimizes the production process. At the same time, it monitors batch consistency, prevents failure risks, and accurately verifies the hardness and surface hardening layer of key parts such as threads to ensure that the product meets international standards and improves the reliability and market competitiveness of screws.

-

Attack Speed MachineThe speed machine can greatly improve the quality control level of finished screw products through high-speed and high-precision automated inspection, reduce labor costs and the risk of missed inspections, and is an indispensable key equipment in the upgrade of intelligent manufacturing.

-

Torque testing machineThe torque tester can accurately quantify the torque performance of screws, providing key data support for product design verification, production process optimization and terminal application reliability.

-

Second dimension imagerDuring the inspection, non-contact image analysis and digital measurement technology are used to achieve fast and accurate inspection of screw geometry, form and position tolerances, and surface features. This is especially suitable for all-round quality control of complex contours and tiny screws.

-

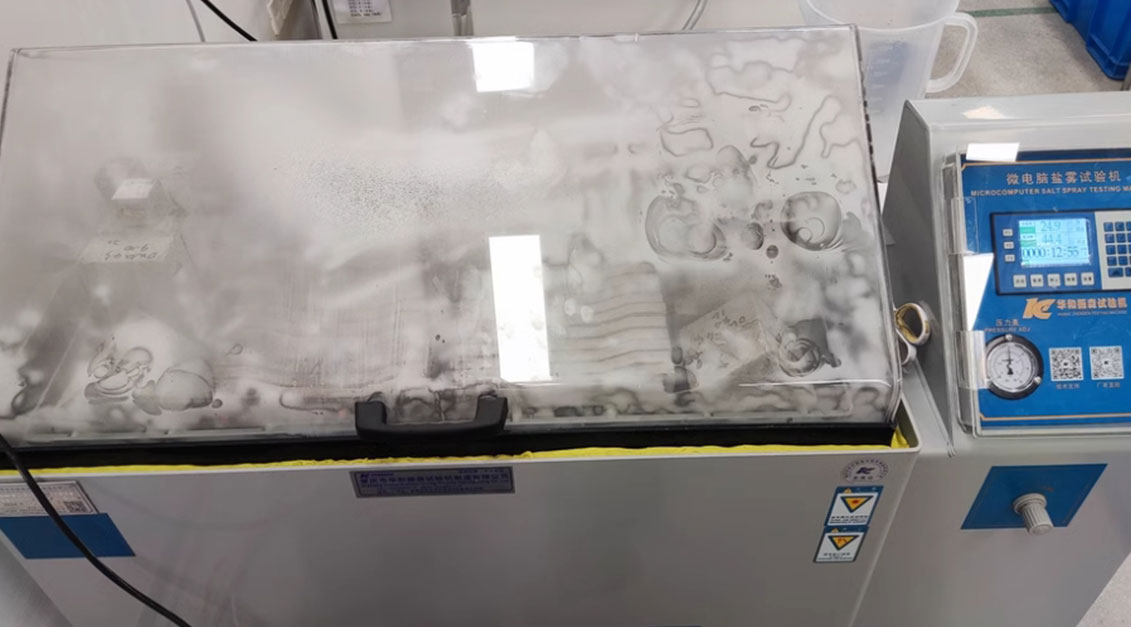

Salt spray test machineBy simulating harsh environments such as marine atmosphere and industrial pollution, the anti-rust ability of screw surface treatment (such as electroplating and coating) is accelerated to ensure its long-term reliability in real-world usage scenarios.

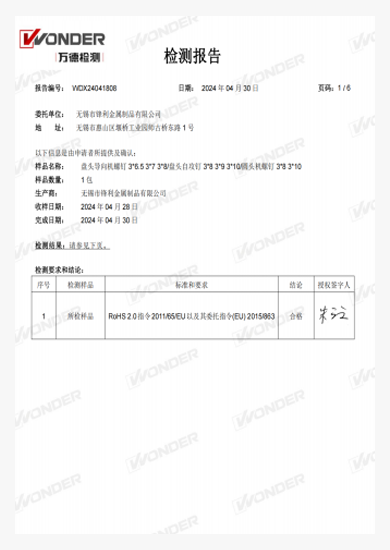

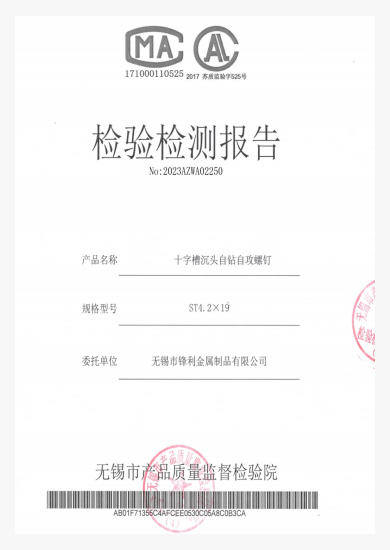

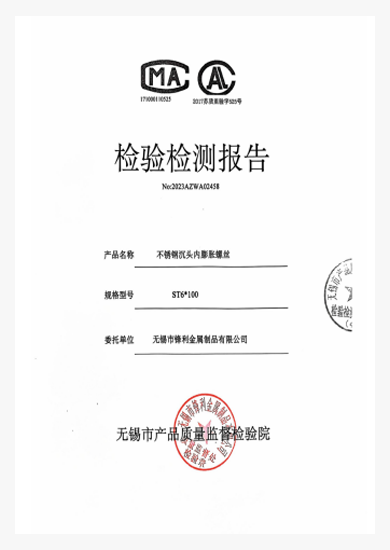

Strict Quality Control And Product Testing

We have our own laboratories and advanced testing equipment in the industry. After finished product production, heat treatment and surface treatment, we will conduct a series of quality tests on the products to ensure the quality of the products before leaving the factory and meet the customer's product testing requirements.

+86-15052135118

+86-15052135118

Español

Español

Get In Touch

Get In Touch